- Working Hours: Mon-Fri 09.00 - 18.00

VTC Series – Automatic Bonnell Spring Transfer Machine

VTC 100 Automatic Bonnell Transfer Machine VTC Series

The solution for full automated bonnell production.

Veysel Kutuklu Mattress Machinery has developed the VTC 100 Machine, with the aspiration to provide a robust machine that can serve for many years mattress and spring unit producer.

The VTC 100 can handle unlimited range of different bonnell spring units for all kinds of mattresses and furnitures thanks to his great flexibility. This machine is built to achieve highest productivity with the maximum speed in the production of bonnell spring units.

Automatic Bonnell Spring Transfer Machine

Bonnell Production in 5 Steps

- The VTC 100 is designed to achieve the highest productivity for the production of bonnell spring units. The improved transfer mechanism, the updated software with new automation program, the new options for furniture spring units ensures the best experience for the production of any type of bonnell spring units.

- The VTC 100 achieves a lean and robust machine structure because of the usage of highest quality materials in every detail.

- Consistently High Performance

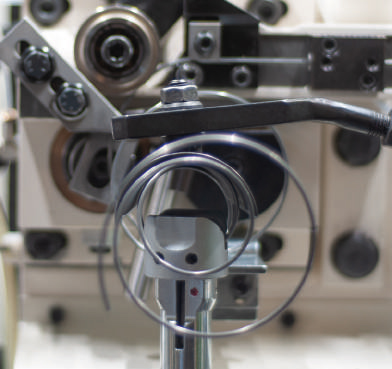

- Improved Transfer Mechanism

- More Flexible Production

- Full Automated Program

- Optimized Design for Furniture Spring Units

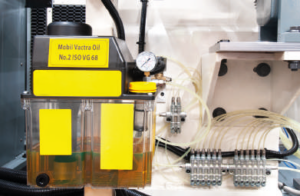

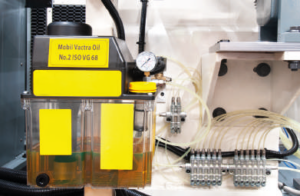

Automatic Lubrication System

+ The automatic lubrication system ensures a periodic oiling of 22 points on the machine

+ The time frames for the periodic lubrication can easily set up on the display

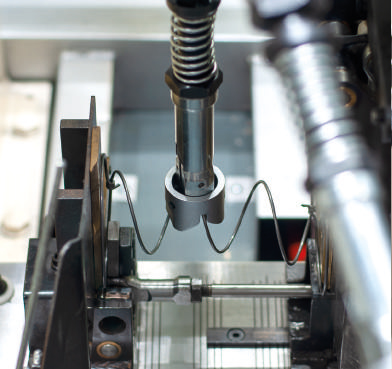

Digital Heat Treatment

The digital heat treatment provides maximum durability to the bonnell springs

+ The temperature can easily set up on the display

+ The heat treatment ensures that every spring is stress-relieved and strengthened

+ This process is eliminating sag of springs

Easy Height Settings

VTC 100 offers the easiest height

setting technology which can adjusted on the touchscreen display

+ This feature enables to adjust the spring height completely automatic

+ Spring height adjustments are made on the precise linear adjustment tool

| Feature | VTC-100 | VTC-200 |

|---|---|---|

| Spring Type | Bonnell | Bonnell |

| Performance | 80 springs / minute | 80 springs / minute |

| Production Capacity | 38,400 springs / 8 hours | 38,400 springs / 8 hours |

| For Single Mattress | Approx. 210 carcasses (90x190cm, 8×23 springs) | Approx. 210 carcasses (90x190cm, 8×23 springs) |

| For Double Mattress | Approx. 130 carcasses (140x190cm, 13×23 springs) | Approx. 130 carcasses (140x190cm, 13×23 springs) |

| Outer Spring Diameter | 70 mm – 96 mm | 70 mm – 96 mm |

| Standard | Ø 80-92 mm, Max. 18 Jaw, 1.9-2.4 mm | Ø 80-92 mm, Max. 18 Jaw, 1.9-2.4 mm |

| Optional | Ø 80-96 mm, Max. 18 Jaw, 1.9-2.4 mm Ø 70-78 mm, Max. 23 Jaw, 1.9-2.2 mm Ø 70-75 mm, Max. 25 Jaw, 1.9-2.2 mm | Ø 80-96 mm, Max. 18 Jaw, 1.9-2.4 mm Ø 70-78 mm, Max. 23 Jaw, 1.9-2.2 mm Ø 70-75 mm, Max. 25 Jaw, 1.9-2.2 mm |

| Middle Spring Diameter | 40 mm – 55 mm | 40 mm – 55 mm |

| Spring Height | 75 mm – 160 mm | 75 mm – 180 mm |

| Standard | 120 mm – 140 mm (5 turns) | 120 mm – 140 mm (5 turns) |

| Optional | 75 mm – 120 mm (4 turns) 140 mm – 160 mm (6 turns) | 75 mm – 120 mm (4 turns) 140 mm – 180 mm (6 turns) |

| Wire Diameter | 1.9 mm – 2.4 mm | 1.9 mm – 2.4 mm |

| Spiral Wire Diameter | 1.3 mm – 1.4 mm | 1.3 mm – 1.4 mm |

| Working Width | 2000 mm | 2000 mm |

| Power Consumption | Approx. 18 kW | Approx. 18 kW |

| Power Requirement | Three-phase 380V, Frequency: 50-60 Hz, Input Fuse: 63 A, Cable: 4 x 10mm² | Three-phase 380V, Frequency: 50-60 Hz, Input Fuse: 63 A, Cable: 4 x 10mm² |

| Operating Temperature | 0° C – 40° C | 0° C – 40° C |

| Weight | Approx. 4,800 kg | Approx. 4,800 kg |

| Wire Basket Capacity | 1,000 kg | 1,000 kg |

| Spiral Wire Basket Capacity | 2 x 850 kg | 2 x 850 kg |

| Control System | Mitsubishi Motion Control System | Mitsubishi Motion Control System |

With excellent spiral knotting options there is possibility to change the irmness of the springs units.

(A) 4-5 Knotting System

(B) 4-4 Knotting System

(C) 4-3 Knotting System

The 4-5 knotting of the spiral wire allows to produce spring units with maximum irmness. This system reduces the range of motion for the bonnell springs.

The 4-4 knotting of the spiral wire ensures the production of spring units with medium irmness. This system allows a small degree of motion for the bonnell springs. The working range of this knotting system is for springs in the diameter between 80-96mm and wire diameter between 1.9-2.4mm.

The 4-3 spiral wire knotting provides the production bonnell springs with maximum range of motion. This knotting system is designed for mini bonnell springs in the diameter 70-78mm and the wire diameter 1.9-2.2mm. This system offers the ideal solution to increase the number of springs on bonnell spring units.

Remote Control

+ Remote control system allows the access to error reports by our service agents

+ This feature allows remote controlled software updates on machines with an internet connection by our service team

+ Access to all machines from one server

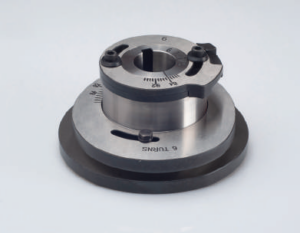

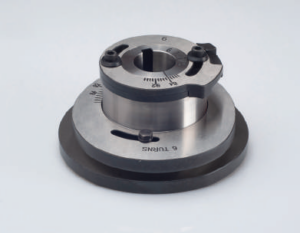

Cam Unit (4, 6 Turns)

+ The optional cam units allowing the production of bonnell spring with 4 turns or 6 turns

+ The optional cam units allowing the production of bonnell spring with 4 turns or 6 turns

+ The cam unit have to replaced together with two gears

+ The standard equipment includes 5 turns cam unit

Span Centring Base

+ The span centring bases are placed at both of the knotting positions on the machine

+ The span centring bases are placed at both of the knotting positions on the machine

+ The different options of span centring base sets allows the production of bonnell spring with different spring diameter

+ The working range for each set is limited to 3mm

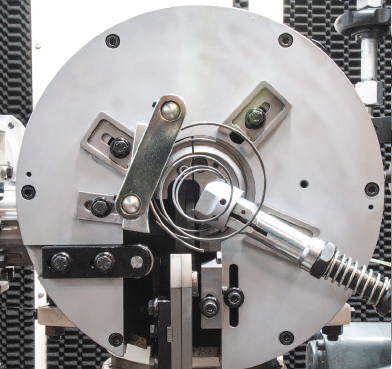

Additional Jaws

+ Additional jaws can be installed on the machine to raise the number of the spring on the spring units

+ Additional jaws can be installed on the machine to raise the number of the spring on the spring units

+ The maximum jaw capacity is 25 pieces on the transfer machine

+ The standard equipment of the machine includes 18 jaws

- The VTC 100 is designed to achieve the highest productivity for the production of bonnell spring units. The improved transfer mechanism, the updated software with new automation program, the new options for furniture spring units ensures the best experience for the production of any type of bonnell spring units.

- The VTC 100 achieves a lean and robust machine structure because of the usage of highest quality materials in every detail.

- Consistently High Performance

- Improved Transfer Mechanism

- More Flexible Production

- Full Automated Program

- Optimized Design for Furniture Spring Units

Automatic Lubrication System

+ The automatic lubrication system ensures a periodic oiling of 22 points on the machine

+ The time frames for the periodic lubrication can easily set up on the display

Digital Heat Treatment

The digital heat treatment provides maximum durability to the bonnell springs

+ The temperature can easily set up on the display

+ The heat treatment ensures that every spring is stress-relieved and strengthened

+ This process is eliminating sag of springs

Easy Height Settings

VTC 100 offers the easiest height

setting technology which can adjusted on the touchscreen display

+ This feature enables to adjust the spring height completely automatic

+ Spring height adjustments are made on the precise linear adjustment tool

| Feature | VTC-100 | VTC-200 |

|---|---|---|

| Spring Type | Bonnell | Bonnell |

| Performance | 80 springs / minute | 80 springs / minute |

| Production Capacity | 38,400 springs / 8 hours | 38,400 springs / 8 hours |

| For Single Mattress | Approx. 210 carcasses (90x190cm, 8×23 springs) | Approx. 210 carcasses (90x190cm, 8×23 springs) |

| For Double Mattress | Approx. 130 carcasses (140x190cm, 13×23 springs) | Approx. 130 carcasses (140x190cm, 13×23 springs) |

| Outer Spring Diameter | 70 mm – 96 mm | 70 mm – 96 mm |

| Standard | Ø 80-92 mm, Max. 18 Jaw, 1.9-2.4 mm | Ø 80-92 mm, Max. 18 Jaw, 1.9-2.4 mm |

| Optional | Ø 80-96 mm, Max. 18 Jaw, 1.9-2.4 mm Ø 70-78 mm, Max. 23 Jaw, 1.9-2.2 mm Ø 70-75 mm, Max. 25 Jaw, 1.9-2.2 mm | Ø 80-96 mm, Max. 18 Jaw, 1.9-2.4 mm Ø 70-78 mm, Max. 23 Jaw, 1.9-2.2 mm Ø 70-75 mm, Max. 25 Jaw, 1.9-2.2 mm |

| Middle Spring Diameter | 40 mm – 55 mm | 40 mm – 55 mm |

| Spring Height | 75 mm – 160 mm | 75 mm – 180 mm |

| Standard | 120 mm – 140 mm (5 turns) | 120 mm – 140 mm (5 turns) |

| Optional | 75 mm – 120 mm (4 turns) 140 mm – 160 mm (6 turns) | 75 mm – 120 mm (4 turns) 140 mm – 180 mm (6 turns) |

| Wire Diameter | 1.9 mm – 2.4 mm | 1.9 mm – 2.4 mm |

| Spiral Wire Diameter | 1.3 mm – 1.4 mm | 1.3 mm – 1.4 mm |

| Working Width | 2000 mm | 2000 mm |

| Power Consumption | Approx. 18 kW | Approx. 18 kW |

| Power Requirement | Three-phase 380V, Frequency: 50-60 Hz, Input Fuse: 63 A, Cable: 4 x 10mm² | Three-phase 380V, Frequency: 50-60 Hz, Input Fuse: 63 A, Cable: 4 x 10mm² |

| Operating Temperature | 0° C – 40° C | 0° C – 40° C |

| Weight | Approx. 4,800 kg | Approx. 4,800 kg |

| Wire Basket Capacity | 1,000 kg | 1,000 kg |

| Spiral Wire Basket Capacity | 2 x 850 kg | 2 x 850 kg |

| Control System | Mitsubishi Motion Control System | Mitsubishi Motion Control System |

With excellent spiral knotting options there is possibility to change the irmness of the springs units.

(A) 4-5 Knotting System

(B) 4-4 Knotting System

(C) 4-3 Knotting System

The 4-5 knotting of the spiral wire allows to produce spring units with maximum irmness. This system reduces the range of motion for the bonnell springs.

The 4-4 knotting of the spiral wire ensures the production of spring units with medium irmness. This system allows a small degree of motion for the bonnell springs. The working range of this knotting system is for springs in the diameter between 80-96mm and wire diameter between 1.9-2.4mm.

The 4-3 spiral wire knotting provides the production bonnell springs with maximum range of motion. This knotting system is designed for mini bonnell springs in the diameter 70-78mm and the wire diameter 1.9-2.2mm. This system offers the ideal solution to increase the number of springs on bonnell spring units.

Remote Control

+ Remote control system allows the access to error reports by our service agents

+ This feature allows remote controlled software updates on machines with an internet connection by our service team

+ Access to all machines from one server

Cam Unit (4, 6 Turns)

+ The optional cam units allowing the production of bonnell spring with 4 turns or 6 turns

+ The optional cam units allowing the production of bonnell spring with 4 turns or 6 turns

+ The cam unit have to replaced together with two gears

+ The standard equipment includes 5 turns cam unit

Span Centring Base

+ The span centring bases are placed at both of the knotting positions on the machine

+ The span centring bases are placed at both of the knotting positions on the machine

+ The different options of span centring base sets allows the production of bonnell spring with different spring diameter

+ The working range for each set is limited to 3mm

Additional Jaws

+ Additional jaws can be installed on the machine to raise the number of the spring on the spring units

+ Additional jaws can be installed on the machine to raise the number of the spring on the spring units

+ The maximum jaw capacity is 25 pieces on the transfer machine

+ The standard equipment of the machine includes 18 jaws

Userfriendly design, easy handling and the highest security standards combined in the VTC 100 .

The VTC 100 machine ensures an user-friendly design that allows a simple entry into assembly part of the machine.

The simple accessibility enables adjustments on the jaw system. The opening system of the assembly part is working completely automatic and there is no need to push or pull on the machine. The safety light curtains protects the operator of the machine.

During the adjustments by operator the safety system not allows to close the assembly part of the machine.

Download Brochures

VTC Series

Take your bonnell production to the next level.